Rich experience in embedded products for medical and special environments. Widely adopted by universities and research institutions! Simple mock-up production available. *Case study materials are currently being distributed.

At Stay Electronics Co., Ltd., we are engaged in the design, development, manufacturing, and sales of flexible printed circuits (FPC).

We are equipped with prototyping facilities such as UV-YAG laser systems and cutting plotters, as well as inspection equipment like image dimension measuring instruments, allowing us to provide consistent support from design to prototyping, manufacturing, and inspection. With extensive manufacturing experience in FPCs for medical devices, we maintain a wide range of materials in stock and can flexibly respond to and propose solutions for customer requests under special conditions.

★ We also respond to requests for mock-up production!

Whether it's challenges that other companies couldn't solve, stalled projects, or if you have never used flexible circuits before and just want to grasp the concept, please feel free to contact us for inquiries and consultations.

【Examples of Flexible Circuit Board Development】

◎ FPC for ultrasound diagnostic probes

◎ FPC for superconducting devices operating at -269°C

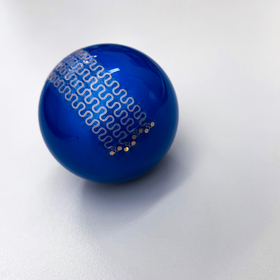

◎ FPC for motor field winding

◎ FPC for ATM security monitoring, among others

*Some development examples can be viewed via "PDF Download." Please feel free to reach out for inquiries.

![[Design and Production Example] Coil_FPC for Motor Field Windings](https://image.mono.ipros.com/public/product/image/396/2000618456/IPROS87961089620937907596.png?w=280&h=280)